Manual Guide i Operators manual Page 322

Operators manual

C.CUSTOMIZATION BY THE MACHINE TOOL BUILDER B-63874EN-1/02

- 314 -

C.2.2 Recalculation Processing Using a Measurement Result List

In manual measurement and automatic measurement using the set-up

guidance functions, measurement results are stored in macro variables

for a measurement result list. A calculation using this measurement

result data can be made with a custom macro program or P-CODE

macro program.

This calculation capability can be used when multiple measurement

cycles are involved, and feedback operation is not performed in each

measurement but feedback operation is performed by recalculating

feedback values finally based on the results of individual

measurements.

Subprogram for acquiring data from the measurement result list

To acquire measurement results from the measurement result list, call

the following P-CODE macro program:

O3890: Subprogram for acquiring measurement results from the

measurement result list

Call format: G65P3890 Q[measurement-result-number]

Input: Number of a measurement result on the measurement result list

(The number "1" is assigned to the latest measurement result.)

Output: Measurement result data (P-CODE macro variable)

(Output data)

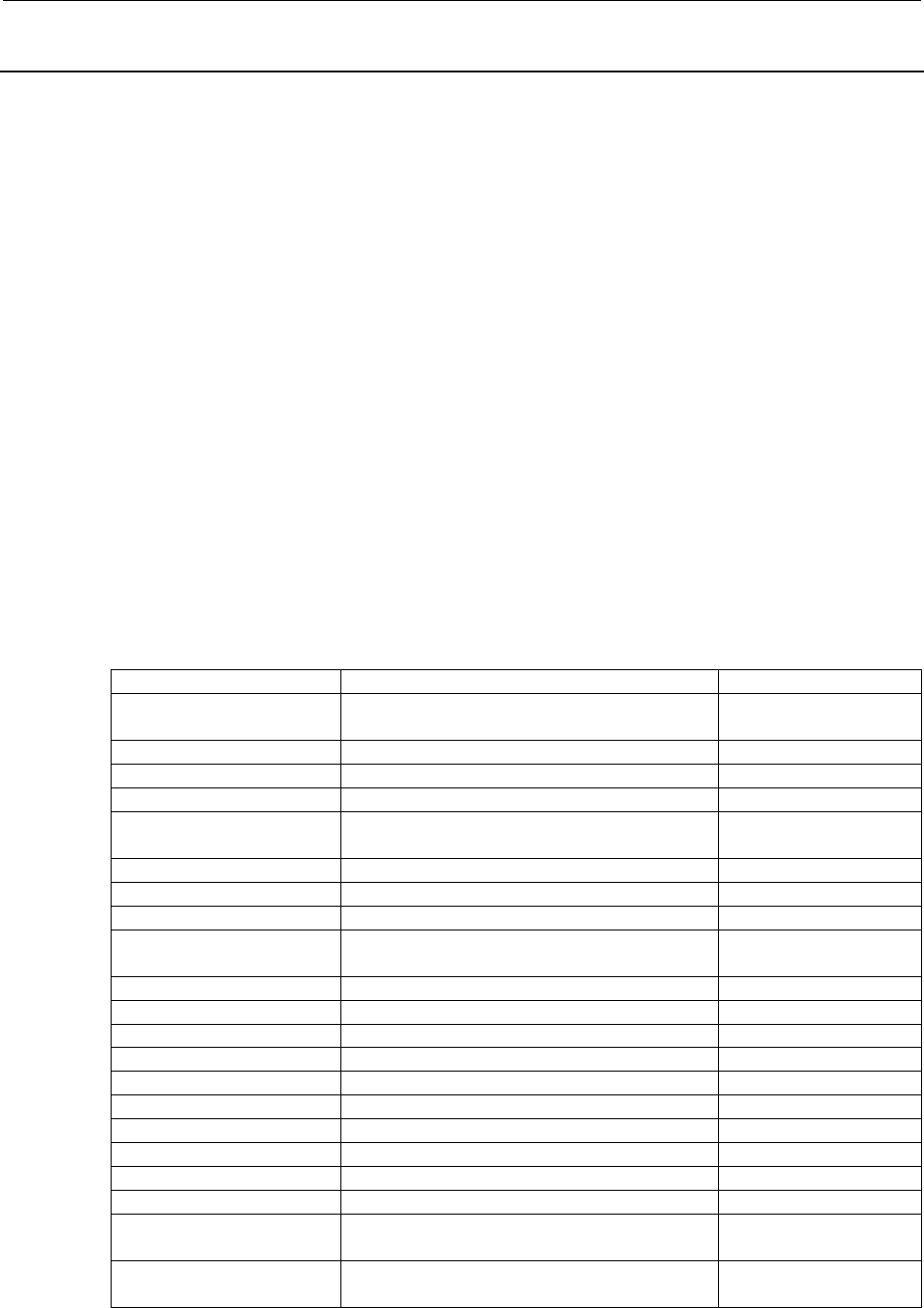

Variable number Description Meaning of value

#[Parameter No.12383+50] Measurement type

Measurement type

number

#[Parameter No.12383+51] Distinction between manual and automatic 1:Manual, 2:Automatic

#[Parameter No.12383+52] Date

#[Parameter No.12383+53] Time

#[Parameter No.12383+54] Decision result (OK/NG/FB/-)

1:No decision, 1:NG,

3:OK, 4:Feedback

#[Parameter No.12383+55] Setting destination Described later

#[Parameter No.12383+56] Setting destination details Described later

#[Parameter No.12383+57] Setting destination compensation type Described later

#[Parameter No.12383+58]

Setting destination offset number/

measurement condition group number

Described later

#[Parameter No.12383+59] Measurement result X

#[Parameter No.12383+60] Measurement result Y

#[Parameter No.12383+61] Measurement result Z

#[Parameter No.12383+62] Measurement result C

#[Parameter No.12383+63] Measurement result Diameter, width

#[Parameter No.12383+66] Target value X

#[Parameter No.12383+67] Target value Y

#[Parameter No.12383+68] Target value Z

#[Parameter No.12383+69] Target value C

#[Parameter No.12383+70] Target value Diameter, width

#[Parameter No.12383+73]

Setting Workpiece coordinate system X, touch

sensor position X

#[Parameter No.12383+74]

Setting Workpiece coordinate system Y, touch

sensor position Y

Contents Summary of Manual Guide i Operators manual

- Page 1SET-UP GUIDANCE FUNCTIONS OPERATOR’S MANUAL B-63874EN-1/02

- Page 2• No part of this manual may be reproduced in any form. • All specifications and designs are subject to change without notice. The export of this product is subject to the authorization of the government of the country from where the product is exported. In this manual we have tried as much as possi

- Page 3B-63874EN-1/02 PREFACE PREFACE Using the set-up guidance functions of MANUAL GUIDE i requires the set-up guidance options. Probes, touch sensors, and other measuring instruments are required to enable the set-up guidance. Refer to the manual published by the machine tool builder of your machine for

- Page 4

- Page 5B-63874EN-1/02 TABLE OF CONTENTS TABLE OF CONTENTS PREFACE.................................................................................................. p-1 1 MANUAL MEASUREMENT FUNCTIONS..............................................1 1.1 SELECTING THE MEASURE SCREEN.............................

- Page 6TABLE OF CONTENTS B-63874EN-1/02 2.2.2 Probe Length Measurement................................................................................... 89 2.2.3 Stylus Ball Diameter Measurement....................................................................... 93 2.2.4 Stylus Ball Center Offset Measu

- Page 7B-63874EN-1/02 TABLE OF CONTENTS 2.8.3 End Face (Z-axis Direction) Measurement ......................................................... 219 2.8.4 Outside Diameter Measurement .......................................................................... 220 2.8.5 Inside Diameter Measurement............

- Page 8TABLE OF CONTENTS B-63874EN-1/02 4.1.1 Displaying the RESULT Screen.......................................................................... 271 4.1.2 Data Displayed on the RESULT Screen.............................................................. 272 4.1.3 Clearing Measurement Result List Data...

- Page 9B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS 1 MANUAL MEASUREMENT FUNCTIONS -1-�

- Page 101.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 1.1 SELECTING THE MEASURE SCREEN 1.1.1 Selecting CALIBRATE <1> The following main menu soft keys are displayed when the machine is in the manual operation mode. <2> Press the [MESURE] key. The menu for the measurement preparation function appears. <3> Us

- Page 11B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS 1.1.2 Selecting TOOL MESUR <1> The following main menu soft keys are displayed when the machine is in the manual operation mode. <2> Press the [MESURE] key. The menu for the measurement preparation function appears. <3> Press the [→] menu select screen c

- Page 121.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 1.1.3 Selecting WORK SET <1> The following main menu soft keys are displayed when the machine is in the manual operation mode. <2> Press the [MESURE] key. The menu for the measurement preparation function appears. <3> Press the [→] cursor key on the meas

- Page 13B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS 1.1.4 Selecting MEASURE <1> The following main menu soft keys are displayed when the machine is in the manual operation mode. <2> Press the [MESURE] key. The menu for the measurement preparation function appears. <3> Press the [→] cursor key on the measu

- Page 141.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 1.2 CALIBRATION 1.2.1 TOUCH SENSOR POSITION MEASUREMENT Measurement procedure <1> Select TOUCH SENSOR POSITION MEASUREMENT from the measurement preparation function menu. <2> Get the reference tool close to the touch sensor by moving it manually. NOTE Pl

- Page 15B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS <6> Press the [MESURE] soft key. The probe touches the reference workpiece automatically, and the current position of the measurement point is displayed as the measurement result. <7> Press the [→] cursor key. The "SET" screen appears. <8> Specify a cond

- Page 161.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 <11>After entering the necessary data, press the [SET] soft key. The measurement result is set up as the measurement preparation data. Measurement Measurements are made as follows: First measurement cycle Second measurement cycle Tool Tool length α Measu

- Page 17B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS 1.2.2 PROBE LENGTH CALIBRATION Measurement procedure <1> Select PROBE LENGTH CALIBRATION from the measurement preparation function menu. <2> Get the probe close to the measurement reference workpiece such as a ring gauge by moving it manually. NOTE Place

- Page 181.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 <5> Enter the height of the measurement reference workpiece in "REFERENCE WORK HEIGHT." <6> Press the [MESURE] soft key. The probe touches the reference workpiece automatically, and the current position of the measurement point is displayed as the measur

- Page 19B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS <9> Select the "MEASURE CONDITION" for the item to which the measurement result is to be set. The currently set value for the probe length for the measurement condition appears. <10>After selecting the measurement condition, press the [SET] soft key. The

- Page 201.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 Measurement Measurements are made as follows: First measurement cycle Second measurement cycle Probe Probe α Measurement length β start point Workpiece γ top surface Reference workpiece Symbol in the Meaning explanation Feedrate in the first measurement

- Page 21B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS 1.2.3 STYLUS BALL DIAMETER CALIBRATION Measurement procedure <1> Select STYLUS BALL DIAMETER CALIBRATION from the measurement preparation function menu. <2> Enter the diameter of the measurement reference workpiece in "REFERENCE WORK DIAMETER." <3> Press

- Page 221.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 <5> In "MEASURE CONDITION," select a measure condition. <6> Place the probe in the first measurement start position for the measurement reference workpiece such as a ring gauge by moving it manually. <7> In "1ST PT. MEASURE DIRECT," select a measurement

- Page 23B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS <9> Perform measurement for the second, third, and fourth points in the same manner as for the first point. <10>Press the [→] cursor key. The "SET" screen appears. <11>Using a number, specify a condition for which the measurement result is to be set by s

- Page 241.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 <13>After selecting the measurement condition, press the [SET] soft key. The measurement result is set as the measurement preparation data. Measurement Measurements are made as follows: First measurement cycle Measurement Second measurement cycle start p

- Page 25B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS 1.2.4 STYLUS OFFSETS CALIBRATION-A (*) The spindle orientation function is used for this function. Measurement procedure <1> Select STYLUS OFFSETS CALIBRATION-A from the measurement preparation function menu. <2> Enter the diameter of the measurement ref

- Page 261.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 <4> Press the [→] cursor key. The "SET" screen appears. <5> Specify a condition for which the measurement result is to be set by selecting it from the two or more "MEASURE CONDITION" items, using a number. The number corresponding to the measurement cond

- Page 27B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS Measurement Measurements are made as follows: First measurement cycle Measurement Second measurement cycle start point α β Measurement γ surface Symbol in the Meaning explanation Feedrate in the first measurement cycle f1 Approach distance in the first m

- Page 281.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 1.2.5 STYLUS OFFSETS CALIBRATION-B NOTE It is necessary to place a reference workpiece such as a ring gauge accurately on the table whose center position is known. Measurement procedure <1> Select STYLUS OFFSETS CALIBRATION-B from the measurement prepara

- Page 29B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS NOTE The same measurement procedure as for "STYLUS BALL DIAMETER CALIBRATION" applies to "STYLUS OFFSETS CALIBRATION-B." See "STYLUS BALL DIAMETER CALIBRATION" for details. <4> Press the [→] cursor key. The "SET" screen appears. <5> Using a number, speci

- Page 301.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 <7> After selecting the measurement condition, press the [SET] soft key. The measurement result is set as the measurement preparation data. Measurement Measurements are made as follows: NOTE The same measurement procedure as for STYLUS BALL DIAMETER CALI

- Page 31B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS 1.3 TOOL MEASUREMENT Measurement procedure <1> Select TOOL MEASUREMENT from the tool measurement menu. <2> If a measurement tool was already selected, go to the “MEASURE” screen. <3> Place the spindle in a place where it is safe to exchange the tool. <4>

- Page 321.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 <9> In "MEASURE CONDITION," select a measure condition. <10>Set up "MEASURE CONDITION." If more than one measurement condition can be specified in "TOUCH SENSOR POSITION MEASUREMENT" for measurement preparation, specify which measurement condition is to

- Page 33B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS <12>After performing measurement, press the [→] cursor key to select "T-TOOL." If you want to specify a milling tool offset number as the item for which the offset value is to be set, go to select "M-TOOL." NOTE With the CNC for a machining center, the “

- Page 341.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 <15>After entering the necessary data, press the [SET] soft key. The measurement result is set as the tool offset. NOTE When the "tool geometry/wear offset" function is available, the tool wear offset is specified as 0 if the offset obtained in measureme

- Page 35B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS <19>In "OFFSET KIND," specify an offset value for which the measurement result is to be set. NOTE The "tool offset memory B" and "tool offset memory C" functions are options. (The "tool offset memory B" option is unavailable on the NC for complex machini

- Page 361.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 NOTE Before starting tool exchange, be sure to place the spindle in such a safe place that the tool will not touch any other machine portion or the workpiece. Similarly, before starting measurements, be sure to place the tool in such a safe place that th

- Page 37B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS Measurement Measurements are made as follows: First measurement cycle Second measurement cycle Tool Tool length D α Measurement β start point α γ Touch Touch sensor sensor top surface Symbol in the Meaning explanation Feedrate in the first measurement cy

- Page 381.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 Referencing the tool offset value setting screen Press the [OFFSET] soft key on the tool measurement screen. The following screen appears. <1> The data displayed here is the same as for the tool offset value entry screen of the setting menu. <2> When the

- Page 39B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS 1.4 WORK SET 1.4.1 SINGLE SURFACE MEASUREMENT PROBE Z-AXIS Measurement procedure <1> Select "SINGLE SURFACE MEASUREMENT PROBE Z- AXIS" from the centering menu select screen. <2> By moving the probe manually, get it close to the measurement point where me

- Page 401.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 <6> After entering "MEASURE DIRECTION," press, the [MESURE] soft key. The probe touches the measurement point automatically, and the current position of the measurement point is displayed as the measurement result. <7> After making measurements, press th

- Page 41B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS <9> In "WORK COORDINATE NO. T," specify a workpiece coordinate system for which the measurement result is to be set. (Descriptions of values to be entered) For G54 → Key in '54'. For G59→ Key in '59'. If the coordinate system to be set is anything betwee

- Page 421.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 <11>In "WORK COORDINATE VALUE," specify what coordinates in the workpiece coordinate system are to be assigned to the measurement point. <12>Press the [SET] soft key. A value calculated from the measurement result and the value specified in "WORK COORIDA

- Page 43B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS <14>The measurement result appears on the screen. If you want to make measurements only, quit the operation here. Set values in "WORK COORDINATE NO. M" and "WORK COORDINATE VALUE." <15>For explanations about what to set, see the specification of operatio

- Page 441.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 Measurement Measurements are made as follows: ● Measuring the end face along the X- or Y-axis First measurement cycle Measurement Second measurement cycle start point α β Measurement γ surface Symbol in the Meaning explanation Feedrate in the first measu

- Page 45B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS ● Measuring the end face along the Z-axis First measurement cycle Second measurement cycle Measurement start point α β Measurement γ surface <1> Get the probe close to the measurement position by moving it manually. <2> When measurement is started, the p

- Page 461.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 1.4.2 SINGLE SURFACE MEASUREMENT PROBE Measurement procedure <1> Select "SINGLE SURFACE MEASUREMENT PROBE X- AXIS" from the centering function menu select screen. The contents of this screen and what data is input on it are the same as for "SINGLE SURFAC

- Page 47B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS <3> Then, the probe returns through the distance β at the rapid traverse rate. Within the range (β + γ) from the current position, the probe moves at a feedrate of f2 to perform the second measurement cycle. <4> After the second measurement cycle, the pr

- Page 481.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 1.4.3 OUTSIDE DIAMETER MEASUREMENT Measurement procedure <1> Select "OUTSIDE DIAMETER MEASUREMENT" from the centering function menu select screen. <2> By moving the probe manually, get it close to the measurement point so that measurement is possible wit

- Page 49B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS <5> When the cursor is placed on "1ST PT. MEASURE DIRECT," the following screen appears. <6> Select a measurement direction from the [+X], [-X], [+Y], [-Y], [+Z], and [-Z] soft keys. Usually, no change is needed. If you want to make measurements on anoth

- Page 501.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 <8> Pressing the [↓] cursor key displays a guide chart for "2ND PT. MEASURE DIRECT." <9> By moving the probe manually, get it close to the second measurement point so that measurement is possible with the movement of the probe along the axis in one direc

- Page 51B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS <12>After measurements are made, placing the cursor on a measurement point displayed on the "MEASURE" screen re- displays the measurement result on that point. Under this condition, pressing the [MESURE] soft key triggers re- measurements on the point. <

- Page 521.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 <14>Based on the measurement results on the four points, the center position is displayed on the screen. If you want to perform measurements only, quit the operation here. The data to be displayed varies depending on what is entered in "MEASURE DIRECTION

- Page 53B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS <19>Pressing the [→] cursor key displays the "M-WORK" screen, on which a milling tool offset number can be specified. For explanations about the operating procedure for this screen, see those for the "T-WORK" screen. NOTE With the CNC for a lathe, the “M

- Page 541.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 Measurement Measurements are made as follows: If [ENABLE] is selected for "ORIENTED SPINDLE STOP," the following operations occur. <1> If the measurement plane is the X-Y plane, and measurements are to be made in the "+X" direction, before starting measu

- Page 55B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS 1.4.4 INSIDE DIAMETER MEASUREMENT Measurement procedure <1> Select "INSIDE DIAMETER MEASUREMENT" from the centering function menu select screen. The items displayed on this screen and the operating procedure for them are the same as for OUTSIDE DIAMETER

- Page 561.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 1.4.5 OUTSIDE WIDTH MEASUREMENT Measurement procedure <1> Select "OUTSIDE WIDTH MEASUREMENT" from the centering function menu select screen. <2> By moving the probe manually, get it close to the first measurement point so that measurement is possible wit

- Page 57B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS (If [Y-Z Z] is selected) <4> Set up "MEASURE CONDITION." <5> Placing the cursor on "1ST PT. MEASURE DIRECT" displays the following screen. <6> Select a measurement direction from the [+X], [-X], [+Y], [-Y], [+Z], and [-Z] soft keys. Usually, no change is

- Page 581.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 <8> Pressing the [↓] cursor key displays a guide chart for "2ND PT. MEASURE DIRECT." <9> By moving the probe manually, get it close to the second measurement point so that measurement is possible with the movement of the probe along the axis in one direc

- Page 59B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS <11>After measurements, press the [→] cursor key to display the "T- WORK" screen. NOTE With the CNC for a machining center, the “T- WORK” screen is not displayed. <12>Based on the measurement results on the two points, the center position and width are d

- Page 601.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 (If [Y-Z Z] is selected) <13>In "WORK COORDINATE NO. T," specify the workpiece coordinate system for which the measurement result is to be set. <14>When a workpiece coordinate system is selected, the current workpiece coordinate system data is displayed

- Page 61B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS Measurement Measurements are made as follows: NOTE The same measurement procedure as for SINGLE SURFACE MEASUREMENT PROBE Z-AXIS applies to the above measurements. See "SINGLE SURFACE MEASUREMENT PROBE Z-AXIS" for details. - 53 -�

- Page 621.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 1.4.6 INSIDE WIDTH MEASUREMENT Measurement procedure <1> Select "INSIDE WIDTH MEASUREMENT" from the centering function menu select screen. NOTE The items displayed on this screen and the operation procedure for them are the same as for OUTSIDE WIDTH MEAS

- Page 63B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS 1.4.7 C AXIS PHASE MEASUREMENT OF OUTSIDE GROOVE Measurement procedure <1> Select "C AXIS PHASE MEASUREMENT OF OUTSIDE GROOVE" from the workpiece measurement menu. <2> By moving the probe manually, get it close to the first measurement point so that meas

- Page 641.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 <6> Pressing the [↓] cursor key displays a guide chart for "2ND PT. MEASURE DIRECT." <7> Retract the probe in the Z-axis direction while keeping it stationary with respect to the X- and Y-axes, and then rotate it around the C-axis. <8> By moving the prob

- Page 65B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS <10>After measurements, press the [→] cursor key to display the "T- WORK" screen. NOTE With the CNC for a machining center, the “T- WORK” screen is not displayed. <11>Based on the measurement results on the two points, the center angle is displayed on th

- Page 661.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 For explanations about the operating procedure for this screen, see those for the "T-WORK" screen. NOTE With the CNC for a lathe, the “M-WORK” screen is not displayed. Measurement Measurements are made as follows: NOTE The same measurement procedure as f

- Page 67B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS 1.4.8 C AXIS PHASE MEASUREMENT OF INSIDE CAVE Measurement procedure <1> Select "C AXIS PHASE MEASUREMENT OF INSIDE CAVE" from the workpiece measurement menu. NOTE The items displayed on this screen and the operating procedure for them are the same as for

- Page 681.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 1.5 MEASURE 1.5.1 SINGLE SURFACE MEASUREMENT PROBE Z-AXIS Measurement procedure <1> Select "SINGLE SURFACE MEASUREMENT PROBE Z- AXIS" from the post-machining inspection menu select screen. The contents of the "MEASURE" screen are the same as for "SINGLE

- Page 69B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS <4> Select a value for "OFFSET KIND," using the soft keys. NOTE 1 The "Y-axis offset" function is an option. 2 The "tool geometry/wear offset" function is an option. If this option is unavailable, neither "GEOMETORY" nor "WEAR" is displayed. <5> In "TARG

- Page 701.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 <6> After entering the necessary data, press the [SET] soft key. The measurement result is set as the tool offset value. NOTE A value displayed as the setting value is added to the offset value for the item specified in OFFSET KIND. <7> Pressing the [→]

- Page 71B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS <9> Select a value for "OFFSET KIND," using the soft keys. NOTE The "tool offset memory B" and "tool offset memory C" functions are options. (The "tool offset memory B" option is unavailable on the NC for complex machining.) <10>In "TARGET VALUE," specif

- Page 721.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 <11>After entering the necessary data, press the [SET] soft key. The measurement result is set as the tool offset value. NOTE A value displayed as the setting value is added to the offset value specified in the item for which the setting value is to be s

- Page 73B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS 1.5.2 SINGLE SURFACE MEASUREMENT PROBE X-AXIS Measurement procedure <1> Select "SINGLE SURFACE MEASUREMENT PROBE X- AXIS" from the post-machining inspection menu select screen. The contents of this screen and the data entered on it are the same as for "S

- Page 741.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 1.5.3 OUTSIDE DIAMETER MEASUREMENT Measurement procedure <1> Select "OUTSIDE DIAMETER MEASUREMENT" from the post-machining inspection menu select screen. The contents of this "MEASURE" screen are the same as for "OUTSIDE DIAMETER MEASUREMENT" on the "WOR

- Page 75B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS <5> In "TARGET VALUE," specify the desired post-machining outside diameter value. After the value is entered, the value obtained by dividing the difference between the target value and the measurement result by 2 then multiplying by the offset value is d

- Page 761.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 NOTE With the CNC for a lathe, the “M-TOOL” screen is not displayed. <8> In "TOOL OFFSET NO. M-SIDE," specify a milling tool offset number. When an offset number is entered, the current offset value for the offset number is displayed on the right section

- Page 77B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS 1.5.4 INSIDE DIAMETER MEASUREMENT Measurement procedure <1> Select "INSIDE DIAMETER MEASUREMENT" from the post- machining inspection menu select screen. The items displayed on this screen and the operating procedure for them are the same as for OUTSIDE D

- Page 781.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 1.5.5 OUTSIDE WIDTH MEASUREMENT Measurement procedure <1> Select "OUTSIDE WIDTH MEASUREMENT" from the post- machining inspection menu select screen. The contents of this "MEASURE" screen are the same as for "OUTSIDE WIDTH MEASUREMENT" on the "WORK SET" m

- Page 79B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS <6> In "TARGET VALUE," specify the desired post-machining groove width value. After the value is entered, the value obtained by multiplying a difference between the target value and the measurement result by the offset value is displayed as the setting v

- Page 801.MANUAL MEASUREMENT FUNCTIONS B-63874EN-1/02 NOTE With the CNC for a lathe, the “M-TOOL” screen is not displayed. <9> Enter a milling tool offset number in "TOOL OFFSET NO. M- SIDE." <10>When an offset number is entered, the current offset value for the offset number is displayed on the right secti

- Page 81B-63874EN-1/02 1.MANUAL MEASUREMENT FUNCTIONS 1.5.6 INSIDE WIDTH MEASUREMENT Measurement procedure <1> Select "INSIDE WIDTH MEASUREMENT" from the post- machining inspection menu select screen. The items displayed on this screen and the operating procedure for them are the same as for OUTSIDE WIDTH M

- Page 822.MEASUREMENT CYCLE B-63874EN-1/02 2 MEASUREMENT CYCLE - 74 -�

- Page 83B-63874EN-1/02 2.MEASUREMENT CYCLE 2.1 MEASUREMENT SCREEN SELECTION In the edit mode, the following main menu soft keys are displayed: (First page: Basic programming menu) - When you press the [+] soft key at the rightmost position, the soft keys for the second page appear. (Second page: Programming

- Page 842.MEASUREMENT CYCLE B-63874EN-1/02 When you press the page key [↓] on this screen, the following screen appears: When you select a cycle to be inserted then press the [SELECT] soft key, the input screen for the selected cycle appears. Selecting a tool measurement menu item When you press the cursor

- Page 85B-63874EN-1/02 2.MEASUREMENT CYCLE Selecting a centering menu item When you press the cursor key [→] while the tool measurement menu selection screen is displayed, the following screen appears: When you press the page key [↓] on this screen, the following screen appears: When you press the page key

- Page 862.MEASUREMENT CYCLE B-63874EN-1/02 When you press the page key [↓] once again on this screen, the following screen appears: When you select a cycle to be inserted then press the [SELECT] soft key, the input screen for the selected cycle appears. Selecting a post-machining inspection menu item When y

- Page 87B-63874EN-1/02 2.MEASUREMENT CYCLE When you press the page key [↓] on this screen, the following screen appears: When you press the page key [↓] again on this screen, the following screen appears: When you select a cycle to be inserted then press the [SELECT] soft key, the input screen for the selec

- Page 882.MEASUREMENT CYCLE B-63874EN-1/02 2.2 CALIBRATION (PROBE Z-AXIS DIRECTION) 2.2.1 Touch Sensor Position Measurement When the reference tool is oriented in the Z-axis direction, the position of the touch sensor for tool measurement is measured. Measurement motion screen When you select "TOUCH SENSOR

- Page 89B-63874EN-1/02 2.MEASUREMENT CYCLE - REF TOOL RADIUS Enter the dimension of the reference tool in the X-axis and Y-axis directions. Enter a numeric value. - SPECIFY OF MEAS. PT. Select a measurement position specification method from the soft keys below. By default, "SETTIN" is selected. When "SETTI

- Page 902.MEASUREMENT CYCLE B-63874EN-1/02 Setting screen - SWITCH DEST. Specify a setting destination for setting calibration data. Make a selection from the soft keys below. By default, "OFFSET" is selected. NOTE If "REF. VALUE" is selected, the result of measurement is set as the calibration data referen

- Page 91B-63874EN-1/02 2.MEASUREMENT CYCLE ±) - FEED BACK RANGE (± If an error obtained from measurement is not within the OK range but is within this feedback range, the measured value is set in the setting destination. If an error obtained from measurement exceeds the feedback range, an alarm is issued. E

- Page 922.MEASUREMENT CYCLE B-63874EN-1/02 Measurement motion Measurement motion is described below. - Measurement of the touch sensor position for measurement in the -Z-axis direction <1> A rapid movement is made from the current position to the approach point (X coordinate,Y coordinate). Here, the approac

- Page 93B-63874EN-1/02 2.MEASUREMENT CYCLE The symbols used above have the following meanings: A: Touch sensor position. If "SETTIN" is selected in "SPECIFY OF MEAS. PT.", A represents the "sensor position for measurement in the -Z direction" of the touch sensor position in the specified measurement conditi

- Page 942.MEASUREMENT CYCLE B-63874EN-1/02 - Measurement of the touch sensor position for measurement in the +X-axis direction <1> A rapid movement is made from the current position to the approach point (X coordinate,Y coordinate). Here, the approach point (X coordinate) represents (touch sensor position A

- Page 95B-63874EN-1/02 2.MEASUREMENT CYCLE - Measurement of the touch sensor position for measurement in the -X-axis direction <1> A rapid movement is made from the current position to the approach point (X coordinate,Y coordinate). Here, the approach point (X coordinate) represents (touch sensor position A

- Page 962.MEASUREMENT CYCLE B-63874EN-1/02 - Measurement of the touch sensor position for measurement in the -Y-axis direction <1> A rapid movement is made from the current position to the approach point (X coordinate,Y coordinate). Here, the approach point (X coordinate) represents the touch sensor positio

- Page 97B-63874EN-1/02 2.MEASUREMENT CYCLE 2.2.2 Probe Length Measurement When the probe is oriented in the Z-axis direction, a probe length measurement is made. Measurement motion screen When you select "PROBE LENGTH CALIBRATION (PROBE Z- AXIS)" on the calibration menu selection screen of the measurement c

- Page 982.MEASUREMENT CYCLE B-63874EN-1/02 Setting screen - OK RANGE (±±) Specify an allowable range of errors obtained from measurement. If the difference between the obtained result of measurement and the probe length of the calibration data currently specified with "MEASUREMENT COND." is within this allo

- Page 99B-63874EN-1/02 2.MEASUREMENT CYCLE Measurement motion Measurement motion is described below. <1> A rapid movement is made from the current position to the point specified by "MEASURE POINT X" and "MEASURE POINT Y". <2> In the Z-axis direction, a rapid movement is made to the approach point (Z coordi

- Page 1002.MEASUREMENT CYCLE B-63874EN-1/02 The symbols used above have the following meanings: T: Height of the surface on which the reference workpiece is placed. ("Machine coordinate of the table surface when a measurement is made in the Z-axis direction" in the measurement condition is referenced.) f: Va

- Page 101B-63874EN-1/02 2.MEASUREMENT CYCLE 2.2.3 Stylus Ball Diameter Measurement The diameters of the stylus ball in the X-axis direction and Y-axis direction are measured. When you select "STYLUS BALL DIAMETER CALIBRATION (PROBE Z-AXIS)" on the calibration menu selection screen of the measurement cycle, t

- Page 1022.MEASUREMENT CYCLE B-63874EN-1/02 - MOVING MEAS. SPEED Enter a feedrate at measurement. Enter a numeric value. - MEASUREMENT POINT Specify the number of measurement points. Enter a numeric value (1 to 4). When no value is entered, 4 (four-point measurement) is assumed. Setting screen - OK RANGE (±±

- Page 103B-63874EN-1/02 2.MEASUREMENT CYCLE NOTE Two stylus ball diameters are set in the calibration data: one in the first axis direction, and the other in the second axis direction. So, the diameter values obtained from measurement are compared in the two directions. If one of the diameters exceeds the fe

- Page 1042.MEASUREMENT CYCLE B-63874EN-1/02 <7> A similar measurement is made in the -X-axis direction and ±Y- axis directions. <8> After the first measurement, a center position for the second measurement is calculated from the measurement result of each point. <9> In the +X-axis direction, a movement is ma

- Page 105B-63874EN-1/02 2.MEASUREMENT CYCLE f: Value of “FEED-RATE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." α: Value of “APPROACH DISTANCE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." β: Va

- Page 1062.MEASUREMENT CYCLE B-63874EN-1/02 2.2.4 Stylus Ball Center Offset Measurement-A The offset between the center of the stylus ball and the center of the spindle is measured. NOTE By using the spindle orientation function, the machine tool builder needs to perform spindle positioning at 0° or 180° bas

- Page 107B-63874EN-1/02 2.MEASUREMENT CYCLE - HEIGHT OF MEAS. PT. Enter the height of a measurement point in the Z-axis direction. Enter a numeric value. - APROCH DISTANCE Specify the move distance from the approach point to the measurement point in the Z-axis direction. Enter a numeric value. - MOVING MEAS.

- Page 1082.MEASUREMENT CYCLE B-63874EN-1/02 ±) - FEED BACK RANGE (± If an offset obtained from measurement is not within the OK range but is within this feedback range, the offset is set in the setting destination. If an offset obtained from measurement exceeds the feedback range, an alarm is issued. Enter a

- Page 109B-63874EN-1/02 2.MEASUREMENT CYCLE Measurement motion Measurement motion is described below. <1> The reference workpiece is placed on the table, then this measurement cycle is executed. <2> When this measurement cycle is executed, a rapid movement is first made from the current position to the point

- Page 1102.MEASUREMENT CYCLE B-63874EN-1/02 The symbols used above have the following meanings: fa: Value of "FEED-RATE FOR APPROACHING START POINT" in the measurement condition of the group number specified in "MEASUREMENT COND." Rapid traverse rate when bit 2 (RPDF) of parameter No. 12380 is set to 1. fb:

- Page 111B-63874EN-1/02 2.MEASUREMENT CYCLE Measurement result When G2003 is executed, center offsets of the stylus ball in the X- axis and Y-axis directions are found from measured values, and are output to the calibration data and macro variables for the result of measurement. - 103 -�

- Page 1122.MEASUREMENT CYCLE B-63874EN-1/02 2.2.5 Stylus Ball Center Offset Measurement-B The offset between the center of the stylus ball and the center of the spindle is measured. NOTE A reference workpiece needs to be accurately placed on a table whose center position is known. When you select "STYLUS OFF

- Page 113B-63874EN-1/02 2.MEASUREMENT CYCLE - APROCH CENTER PT. Y Enter the Y coordinate of the center of the reference workpiece. Enter a numeric value. - HEIGHT OF MEAS. PT. Enter the height of a measurement point in the Z-axis direction. Enter a numeric value. - APROCH DISTANCE Specify the move distance f

- Page 1142.MEASUREMENT CYCLE B-63874EN-1/02 ±) - FEED BACK RANGE (± If an offset obtained from measurement is not within the OK range but is within this feedback range, the offset is set in the setting destination. If an offset obtained from measurement exceeds the feedback range, an alarm is issued. Enter a

- Page 115B-63874EN-1/02 2.MEASUREMENT CYCLE Measurement motion Measurement motion is described below. <1> The reference workpiece is placed on the table, then this measurement cycle is executed. <2> When this measurement cycle is executed, a rapid movement is first made from the current position to the point

- Page 1162.MEASUREMENT CYCLE B-63874EN-1/02 α: Value of “APPROACH DISTANCE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." β: Value of "ESCAPING DISTANCE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND

- Page 117B-63874EN-1/02 2.MEASUREMENT CYCLE 2.3 TOOL MEASUREMENT (TOOL Z-AXIS DIRECTION) 2.3.1 Milling Tool Measurement When the milling tool is oriented in the Z-axis direction, its figures in the tool length direction and tool radius direction are measured. Measurement motion screen When you select "MILLIN

- Page 1182.MEASUREMENT CYCLE B-63874EN-1/02 - SPECIFY OF X SHIFT Select a method of specifying the shift amount from the X coordinate of the touch sensor position for tool measurement to the X coordinate of the tool measurement position. By default, [AUTO] is selected. Choose from the soft keys. When [AUTO]

- Page 119B-63874EN-1/02 2.MEASUREMENT CYCLE Input screen for automatic tool offset value setting (turning side) This screen enables specification for setting a measured value as a tool offset value on the turning side. NOTE With the CNC for a machining center, the "TOOL T" screen is not displayed. - COMP. NU

- Page 1202.MEASUREMENT CYCLE B-63874EN-1/02 - SETTING DEST. (T) Specify a tool offset item in which the result of measurement is to be set. Select a desired item from the following soft keys: NOTE When the tool geometry and wear compensation options are enabled, and a compensation value obtained from measure

- Page 121B-63874EN-1/02 2.MEASUREMENT CYCLE Processing when the OK range and the feedback range are 0 When the Ok range and the feedback range are set to 0, the processing below is performed. <1> When both the OK range and the feedback are set to 0 The result of measurement is not set in the setting destinat

- Page 1222.MEASUREMENT CYCLE B-63874EN-1/02 Input screen for automatic tool offset value setting (milling side) This screen enables specification for setting a measured value as a tool offset value on the milling side. NOTE 1 With the CNC for a lathe, the "TOOL M" screen is not displayed. 2 "32 tool compensa

- Page 123B-63874EN-1/02 2.MEASUREMENT CYCLE Measurement motion Measurement motion is described below. - Measurement of an offset value in the -Z-axis direction (measurement of an offset value in the tool length direction) - When [AUTO] is selected in "SPECIFY OF X, Y, and Z SHIFT" The measurement motion desc

- Page 1242.MEASUREMENT CYCLE B-63874EN-1/02 - Measurement of an offset value in the -Z-axis direction (measurement of an offset value in the tool length direction) - When a soft key other than [AUTO] is selected in "SPECIFY OF X, Y, and Z SHIFT" If the X coordinate of the "sensor position for measurement in

- Page 125B-63874EN-1/02 2.MEASUREMENT CYCLE <4> Next, a rapid return movement is made by β, and a measurement is made in the range from that position to (β + γ) at the specified feedrate F. (Second measurement) <5> Then, a rapid return movement is made by ε in the +Z-axis direction. • If [OFSET-] is selected

- Page 1262.MEASUREMENT CYCLE B-63874EN-1/02 - Measurement of an offset value in the -X-axis direction (measurement of an offset value in the tool radius direction) The measurement motion described below is made when [AUTO] is selected in all input items of “SPECIFY OF X SHIFT”, “SPECIFY OF Y SHIFT”, and “SPE

- Page 127B-63874EN-1/02 2.MEASUREMENT CYCLE <5> Then, a rapid return movement is made by ε in the +X-axis direction. If the coordinates of the "sensor position for measurement in the -X direction" of the touch sensor position are shifted from the coordinates of the tool measurement position, specify the shif

- Page 1282.MEASUREMENT CYCLE B-63874EN-1/02 ε: Value of "ESCAPING DISTANCE FOR 2ND MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." OHSH : Tool length direction offset value OFSD : Tool radius direction offset value G code format When you press the INSERT key aft

- Page 129B-63874EN-1/02 2.MEASUREMENT CYCLE 2.3.2 Turning Tool Measurement When the turning tool is oriented in the Z-axis direction, its figures in the Z-axis and X-axis directions are measured. Measurement motion screen When you select "TURNING TOOL MEASUREMENT (TOOL Z- AXIS)" on the tool measurement menu

- Page 1302.MEASUREMENT CYCLE B-63874EN-1/02 by the next item "OFFSET/DIFFERENCE X" from the X coordinate of the touch sensor position. - OFFSET/DIFFERENCE X This item is displayed when [INPUT] or [DIFFER] is selected in "SPECIFY OF X SHIFT". When [INPUT] is selected, enter the shift amount from the X coordin

- Page 131B-63874EN-1/02 2.MEASUREMENT CYCLE To the other items, the descriptions in "Milling Tool Measurement" are applied. - 123 -�

- Page 1322.MEASUREMENT CYCLE B-63874EN-1/02 Measurement motion Measurement motion is described below. - Measurement of an offset value in the +X-axis direction Z X The measurement motion described below is made when [AUTO] is selected in all input items of “SPECIFY OF X SHIFT”, “SPECIFY OF Y SHIFT”, and “SPE

- Page 133B-63874EN-1/02 2.MEASUREMENT CYCLE <5> Then, a rapid return movement is made by ε in the -X-axis direction. If the coordinates of the "sensor position for measurement in the +X direction" of the touch sensor position are shifted from the coordinates of the tool measurement position, specify the shif

- Page 1342.MEASUREMENT CYCLE B-63874EN-1/02 - Measurement of an offset value in the -Z-axis direction Z X The measurement motion described below is made when [AUTO] is selected in all input items of “SPECIFY OF X SHIFT”, “SPECIFY OF Y SHIFT”, and “SPECIFY OF Z SHIFT”. <1> A rapid movement is made from the cu

- Page 135B-63874EN-1/02 2.MEASUREMENT CYCLE If the coordinates of the "sensor position for measurement in the -Z direction" of the touch sensor position are shifted from the coordinates of the tool measurement position, specify the shift in "SPECIFY OF X, Y, or Z SHIFT". For example, the motion described bel

- Page 1362.MEASUREMENT CYCLE B-63874EN-1/02 Measurement result When G2011 is executed, the result of measurement is output to macro variables for the result of measurement and as a specified tool offset value. - 128 -�

- Page 137B-63874EN-1/02 2.MEASUREMENT CYCLE 2.4 WORK SET (PROBE Z-AXIS DIRECTION) 2.4.1 End Face (X-axis Direction) Measurement The position of an end face in the X-axis direction is measured. When you select "X-AXIS DIRECTION WORK SETUP (PROBE Z- AXIS)" on the centering menu selection screen of the measurem

- Page 1382.MEASUREMENT CYCLE B-63874EN-1/02 Input screen for automatic workpiece offset value setting (turning side) This screen enables specification for setting a measured value as a workpiece origin offset value on the turning side. NOTE With the CNC for a machining center, the "WORK T" screen is not disp

- Page 139B-63874EN-1/02 2.MEASUREMENT CYCLE - OK RANGE (±) Specify an allowable range of errors obtained from measurement. If the difference between the obtained result of measurement and the correct coordinate (input value "MEASURE POINT") is within this allowable range, the absence of errors is assumed, an

- Page 1402.MEASUREMENT CYCLE B-63874EN-1/02 Input screen for automatic workpiece offset value setting (milling side) This screen enables specification for setting a measured value as a workpiece origin offset value on the milling side. The descriptions of the input items are the same as for the turning side.

- Page 141B-63874EN-1/02 2.MEASUREMENT CYCLE Measurement motion Measurement motion is described below. <1> A rapid movement is made from the current position to the approach point (X coordinate,Y coordinate). Here, the approach point (X coordinate) represents ("MEASURE POINT X" - α) when the measurement direc

- Page 1422.MEASUREMENT CYCLE B-63874EN-1/02 G code format When you press the INSERT key after entering necessary data, a G code program in the following format is stored in the machining program memory: G2020 Q P H V L R F W I S Y U J K E ; Measurement result When G2020 is executed, the result of measurement

- Page 143B-63874EN-1/02 2.MEASUREMENT CYCLE 2.4.2 End Face (Y-axis Direction) Measurement The position of an end face in the Y-axis direction is measured. When you select "Y-AXIS DIRECTION WORK SETUP (PROBE Z- AXIS)" on the centering menu selection screen of the measurement cycle, the following screen appear

- Page 1442.MEASUREMENT CYCLE B-63874EN-1/02 Measurement motion <1> A rapid movement is made from the current position to the approach point (X coordinate,Y coordinate). Here, the approach point (X coordinate) is the same as "MEASURE POINT X". The approach point (Y coordinate) represents ("MEASURE POINT Y" –

- Page 145B-63874EN-1/02 2.MEASUREMENT CYCLE 2.4.3 End Face (Z-axis Direction) Measurement The position of an end face in the Z-axis direction is measured. When you select "Z-AXIS DIRECTION WORK SETUP (PROBE Z- AXIS)" on the centering menu selection screen of the measurement cycle, the following screen appear

- Page 1462.MEASUREMENT CYCLE B-63874EN-1/02 Measurement motion Measurement motion is described below. <1> A rapid movement is made from the current position to the point specified by "MEASURE POINT X" and "MEASURE POINT Y". <2> In the Z-axis direction, a rapid movement is made to the approach point (Z coordi

- Page 147B-63874EN-1/02 2.MEASUREMENT CYCLE 2.4.4 Outside Diameter Measurement When the probe is oriented in the Z-axis direction, the center position of the outside diameter of a circle is measured. When you select "OUTSIDE DIAMETER WORK SETUP (PROBE Z-AXIS)" on the centering menu selection screen of the me

- Page 1482.MEASUREMENT CYCLE B-63874EN-1/02 - MOVING MEAS. SPEED Enter a feedrate for measurement. Enter a numeric value. - MEASUREMENT POINT Specify the number of measurement points. Enter a numeric value (1 to 4). - SPINDLE ORIENTATION Specify whether to perform spindle orientation for each measurement poi

- Page 149B-63874EN-1/02 2.MEASUREMENT CYCLE - WORK COORD. VALUE Y Specify the Y coordinate of the measurement point in a specified workpiece coordinate system. Enter a numeric value. - OK RANGE (±) Specify an allowable range of errors obtained from measurement. If the difference between the center coordinate

- Page 1502.MEASUREMENT CYCLE B-63874EN-1/02 Input screen for automatic workpiece offset value setting (milling side) This screen enables specification for setting a measured value as a workpiece origin offset value on the milling side. The descriptions of the input items are the same as for the turning side.

- Page 151B-63874EN-1/02 2.MEASUREMENT CYCLE Measurement motion Measurement motion is described below. <1> A rapid movement is made from the current position to the point specified by ("CENTER POINT X" + ("OUTSIDE DIAMETER"/2 + α +r)) in the X-axis direction and by "CENTER POINT Y" in the Y-axis direction. <2

- Page 1522.MEASUREMENT CYCLE B-63874EN-1/02 β: Value of "ESCAPING DISTANCE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." γ: Value of "OVERLAP DISTANCE FOR MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." ε:

- Page 153B-63874EN-1/02 2.MEASUREMENT CYCLE G code format When you press the INSERT key after entering necessary data, a G code program in the following format is stored in the machining program memory: G2023 Q D H V L R F P M W I J S Y U A B K E ; Measurement result When G2023 is executed, the center of the

- Page 1542.MEASUREMENT CYCLE B-63874EN-1/02 2.4.5 Inside Diameter Measurement When the probe is oriented in the Z-axis direction, the center position of the inside diameter of a circle is measured. When you select "INSIDE DIAMETER WORK SETUP (PROBE Z- axis)" on the centering menu selection screen of the meas

- Page 155B-63874EN-1/02 2.MEASUREMENT CYCLE Measurement motion Measurement motion is described below. <1> A rapid movement is made from the current position to the point specified by ("CENTER POINT X" + ("INSIDE DIAMETER"/2 - α -r)) in the X-axis direction and by "CENTER POINT Y" in the Y-axis direction. <2>

- Page 1562.MEASUREMENT CYCLE B-63874EN-1/02 β: Value of "ESCAPING DISTANCE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." ε: Value of "ESCAPING DISTANCE FOR 2ND MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND

- Page 157B-63874EN-1/02 2.MEASUREMENT CYCLE 2.4.6 Outside Width Measurement When the probe is oriented in the Z-axis direction, the center position of a projection width is measured. When you select "OUTSIDE WIDTH WORK SETUP (PROBE Z- AXIS)" on the centering menu selection screen of the measurement cycle, th

- Page 1582.MEASUREMENT CYCLE B-63874EN-1/02 Input screen for automatic workpiece offset value setting (turning side) This screen enables specification for setting a measured value as a workpiece origin offset value on the turning side. NOTE With the CNC for a machining center, the "WORK T" screen is not disp

- Page 159B-63874EN-1/02 2.MEASUREMENT CYCLE Input screen for automatic workpiece offset value set (milling side) This screen enables specification for setting a measured value as a workpiece origin offset value on the milling side. NOTE With the CNC for a lathe, the "WORK M" screen is not displayed. The desc

- Page 1602.MEASUREMENT CYCLE B-63874EN-1/02 Measurement motion Measurement motion is described below. <1> For measurement in the X-axis direction, a rapid movement is made from the current position to the point specified by ("CENTER POINT X" + ("PROJECTION WIDTH"/2 + α + r)) in the X-axis direction and by "C

- Page 161B-63874EN-1/02 2.MEASUREMENT CYCLE α: Value of “APPROACH DISTANCE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." β: Value of "ESCAPING DISTANCE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND

- Page 1622.MEASUREMENT CYCLE B-63874EN-1/02 2.4.7 Inside Width Measurement When the probe is oriented in the Z-axis direction, the center position of a groove width is measured. When you select "INSIDE WIDTH WORK SETUP (PROBE Z- AXIS)" on the centering menu selection screen of the measurement cycle, the foll

- Page 163B-63874EN-1/02 2.MEASUREMENT CYCLE Measurement motion Measurement motion is described below. <1> For measurement in the X-axis direction, a rapid movement is made from the current position to the point specified by ("CENTER POINT X" + ("GROOVE WIDTH"/2 - α - r)) in the X-axis direction and by "CENTE

- Page 1642.MEASUREMENT CYCLE B-63874EN-1/02 α: Value of “APPROACH DISTANCE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." β: Value of "ESCAPING DISTANCE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND

- Page 165B-63874EN-1/02 2.MEASUREMENT CYCLE 2.4.8 C-axis Outside Width Measurement When the probe is oriented in the Z-axis direction, the center angle of a projection width in the C-axis direction is measured. When you select "C-AXIS OUTSIDE WIDTH WORK SETUP (PROBE Z-AXIS)" on the centering menu selection s

- Page 1662.MEASUREMENT CYCLE B-63874EN-1/02 Input screen for automatic workpiece offset value set (turning side) This screen enables specification for setting a measured value as a workpiece origin offset value on the turning side. NOTE With the CNC for a machining center, the "WORK T" screen is not displaye

- Page 167B-63874EN-1/02 2.MEASUREMENT CYCLE Input screen for automatic workpiece offset value setting (milling side) This screen enables specification for setting a measured value as a workpiece origin offset value on the milling side. NOTE With the CNC for a lathe, the "WORK M" screen is not displayed. The

- Page 1682.MEASUREMENT CYCLE B-63874EN-1/02 Measurement motion Measurement motion is described below. <1> A rapid movement is made from the current position to the point specified by "MEASURE POINT X" and "MEASURE POINT Y". <2> Next, a rapid movement is made in the C-axis direction to the point ("CENTER ANGL

- Page 169B-63874EN-1/02 2.MEASUREMENT CYCLE The symbols used above have the following meanings: fa: Value of "FEED-RATE FOR APPROACHING START POINT" in the measurement condition of the group number specified in "MEASUREMENT COND." Rapid traverse rate when bit 2 (RPDF) of parameter No. 12380 is set to 1. fb:

- Page 1702.MEASUREMENT CYCLE B-63874EN-1/02 2.4.9 C-axis Inside Width Measurement When the probe is oriented in the Z-axis direction, the center angle of a groove in the C-axis direction is measured. When you select "C-AXIS INSIDE WIDTH WORK SETUP (PROBE Z-AXIS)" on the centering menu selection screen of the

- Page 171B-63874EN-1/02 2.MEASUREMENT CYCLE Measurement motion Measurement motion is described below. <1> A rapid movement is made from the current position to the point specified by "MEASURE POINT X" and "MEASURE POINT Y". <2> Next, a rapid movement is made in the C-axis direction to the point specified by

- Page 1722.MEASUREMENT CYCLE B-63874EN-1/02 The symbols used above have the following meanings: fa: Value of "FEED-RATE FOR APPROACHING START POINT" in the measurement condition of the group number specified in "MEASUREMENT COND." Rapid traverse rate when bit 2 (RPDF) of parameter No. 12380 is set to 1. fb:

- Page 173B-63874EN-1/02 2.MEASUREMENT CYCLE 2.5 MEASURE (PROBE Z-AXIS DIRECTION) 2.5.1 End Face (X-axis Direction) Measurement The position of an end face in the X-axis direction is measured. When you select "X-AXIS DIRECTION MEASUREMENT (PROBE Z-AXIS) on the post-machining inspection menu selection screen o

- Page 1742.MEASUREMENT CYCLE B-63874EN-1/02 NOTE With the CNC for a machining center, the "TOOL T" screen is not displayed. - COMP. NUMBER T Enter a tool offset value number with which the result of measurement is to be set. When this item is not entered, the result of measurement is not set as a tool offset

- Page 175B-63874EN-1/02 2.MEASUREMENT CYCLE Input screen for automatic tool offset value setting (milling side) This screen enables specification for setting a measured value as a tool offset value on the milling side. NOTE 1 With the CNC for a lathe, the "TOOL M" screen is not displayed. 2 "32 tool compensa

- Page 1762.MEASUREMENT CYCLE B-63874EN-1/02 Measurement result When G2040 is executed, the compensation value obtained from the measured value is output to macro variables for the result of measurement and as a tool offset value. - 168 -�

- Page 177B-63874EN-1/02 2.MEASUREMENT CYCLE 2.5.2 End Face (Y-axis Direction) Measurement The position of an end face in the Y-axis direction is measured. When you select "Y-AXIS DIRECTION MEASUREMENT (PROBE Z-AXIS) on the post-machining inspection menu selection screen of the measurement cycle, the followin

- Page 1782.MEASUREMENT CYCLE B-63874EN-1/02 2.5.3 End Face (Z-axis Direction) Measurement The position of an end face in the Z-axis direction is measured. When you select "Z-AXIS DIRECTION MEASUREMENT (PROBE Z-AXIS) on the post-machining inspection menu selection screen of the measurement cycle, the followin

- Page 179B-63874EN-1/02 2.MEASUREMENT CYCLE 2.5.4 Outside Diameter Measurement When the probe is oriented in the Z-axis direction, the outside diameter and center position of a circle is measured. When you select "OUTSIDE DIAMETER MEASUREMENT (PROBE Z-AXIS)" on the post-machining inspection menu selection sc

- Page 1802.MEASUREMENT CYCLE B-63874EN-1/02 NOTE With the CNC for a machining center, the "TOOL T" screen is not displayed. - OK RANGE (±) Specify an allowable range of errors obtained from measurement. If the difference between the outside diameter of a circle obtained from measurement and the correct value

- Page 181B-63874EN-1/02 2.MEASUREMENT CYCLE Measurement motion Measurement motion is described below. <1> A rapid movement is made from the current position to the point specified by ("CENTER POINT X" + ("OUTSIDE DIAMETER"/2 + α +r)) in the X-axis direction and by "CENTER POINT Y" in the Y-axis direction. <2

- Page 1822.MEASUREMENT CYCLE B-63874EN-1/02 DIAMETER"/2 + α +r)) in the X-axis direction and by "CENTER POINT Y" in the Y-axis direction. <2> In the Z-axis direction, a rapid movement is made to the approach point ("HEIGHT OF MEAS. PT." + "APROCH DISTANCE"). <3> In the -Z-axis direction, a movement is made t

- Page 183B-63874EN-1/02 2.MEASUREMENT CYCLE Motion depending on the number of measurement points When "MEASUREMENT POINT" is set to 1, a measurement is made in the +X-axis direction only. When "MEASUREMENT POINT" is set to 2, a measurement is made in the +X-axis and -X-axis directions only. When "MEASUREMENT

- Page 1842.MEASUREMENT CYCLE B-63874EN-1/02 2.5.5 Inside Diameter Measurement When the probe is oriented in the Z-axis direction, the inside diameter of a circle is measured. When you select "INSIDE DIAMETER MEASUREMENT (PROBE Z-AXIS)" on the post-machining inspection menu selection screen of the measurement

- Page 185B-63874EN-1/02 2.MEASUREMENT CYCLE Measurement motion Measurement motion is described below. <1> A rapid movement is made from the current position to the point specified by ("CENTER POINT X" + ("INSIDE DIAMETER"/2 - α - r)) in the X-axis direction and by "CENTER POINT Y" in the Y-axis direction. <2

- Page 1862.MEASUREMENT CYCLE B-63874EN-1/02 <2> In the Z-axis direction, a rapid movement is made to the approach point ("HEIGHT OF MEAS. PT." + "APROCH DISTANCE"). <3> In the -Z-axis direction, a movement is made to the position specified by "HEIGHT OF MEAS. PT." at feedrate fb. <4> If "ON" is selected for

- Page 187B-63874EN-1/02 2.MEASUREMENT CYCLE Motion when spindle orientation is enabled The description is the same as for "Outside Diameter Measurement". G code format When you press the INSERT key after entering necessary data, a G code program in the following format is stored in the machining program memo

- Page 1882.MEASUREMENT CYCLE B-63874EN-1/02 2.5.6 Outside Width Measurement When the probe is oriented in the Z-axis direction, the width of a projection is measured. Select "OUTSIDE WIDTH MEASUREMENT (PROBE Z-AXIS)" on the post-machining inspection menu selection screen of the measurement cycle. Measurement

- Page 189B-63874EN-1/02 2.MEASUREMENT CYCLE - FEED BACK RANGE (±) If an error obtained from measurement is not within the OK range but is within this feedback range, the measured value is set in the setting destination. If an error obtained from measurement exceeds the feedback range, an alarm is issued. Ent

- Page 1902.MEASUREMENT CYCLE B-63874EN-1/02 2.5.7 Inside Width Measurement When the probe is oriented in the Z-axis direction, the width of a groove is measured. Select "INSIDE WIDTH MEASUREMENT (PROBE Z-AXIS)" on the post-machining inspection menu selection screen of the measurement cycle. Measurement motio

- Page 191B-63874EN-1/02 2.MEASUREMENT CYCLE 2.6 CALIBRATION (PROBE X-AXIS DIRECTION) 2.6.1 Touch Sensor Position Measurement When the reference tool is oriented in the X-axis direction, the position of the touch sensor for tool measurement is measured. Measurement motion screen When you select "TOUCH SENSOR

- Page 1922.MEASUREMENT CYCLE B-63874EN-1/02 Measurement motion Measurement motion is described below. - Measurement of the touch sensor position for measurement in the -X-axis direction <1> A rapid movement is made from the current position to the approach point (Y coordinate,Z coordinate). Here, the approac

- Page 193B-63874EN-1/02 2.MEASUREMENT CYCLE β: Value of "ESCAPING DISTANCE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." γ: Value of "OVERLAP DISTANCE FOR MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." ε:

- Page 1942.MEASUREMENT CYCLE B-63874EN-1/02 <3> In the range from the approach point to ("CLEARANCE" + γ), a measurement is made at feedrate f. (First measurement) <4> Next, a rapid return movement is made by β, and a measurement is made in the range from that position to (β + γ) at the specified feedrate F.

- Page 195B-63874EN-1/02 2.MEASUREMENT CYCLE G code format When you press the INSERT key after entering necessary data, a G code program in the following format is stored in the machining program memory: G2100 P Q B R K H V L C F W I S Y ; Measurement result When G2100 is executed, the result of measurement i

- Page 1962.MEASUREMENT CYCLE B-63874EN-1/02 2.6.2 Probe Length Measurement When the probe is oriented in the X-axis direction, the length of the probe is measured. Measurement motion screen When you select "PROBE LENGTH CALIBRATION (PROBE X- AXIS)" on the calibration menu selection screen of the measurement

- Page 197B-63874EN-1/02 2.MEASUREMENT CYCLE Setting screen The displayed items are the same as for "Probe Length Measurement" of "CALIBRATION (PROBE Z-AXIS DIRECTION)". Measurement motion Measurement motion is described below. <1> A rapid movement is made from the current position to the point specified by "

- Page 1982.MEASUREMENT CYCLE B-63874EN-1/02 The symbols used above have the following meanings: T: Height of the surface on which the reference workpiece is placed. ("HEIGHT OF PLANE PUT REFERENCE WORK (X)" on the measurement condition screen is referenced.) f: Value of the "FEED-RATE FOR 1ST MEASUREMENT"" i

- Page 199B-63874EN-1/02 2.MEASUREMENT CYCLE 2.6.3 Stylus Ball Diameter Measurement The diameters of the stylus ball in the Y-axis direction and Z-axis direction are measured. When you select "STYLUS BALL DIAMETER CALIBRATION (PROBE X-AXIS)" on the calibration menu selection screen of the measurement cycle, t

- Page 2002.MEASUREMENT CYCLE B-63874EN-1/02 Setting screen The displayed items are the same as for "Stylus Ball Diameter Measurement" of "CALIBRATION (PROBE Z-AXIS DIRECTION)". Measurement motion Measurement motion is described below. <1> The reference workpiece is placed on the table, then this measurement

- Page 201B-63874EN-1/02 2.MEASUREMENT CYCLE <7> A similar measurement is made in the -Y-axis direction and ±Z- axis directions. <8> After the first measurement, a center position for the second measurement is calculated from the measurement result of each point. <9> In the +Y-axis direction, a movement is ma

- Page 2022.MEASUREMENT CYCLE B-63874EN-1/02 f: Value of "FEED-RATE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." α: Value of "APPROACH DISTANCE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." β: Va

- Page 203B-63874EN-1/02 2.MEASUREMENT CYCLE 2.6.4 Stylus Ball Center Offset Measurement-A The offset between the center of the stylus ball and the center of the spindle is measured. NOTE By using the spindle orientation function, the machine tool builder needs to perform spindle positioning at 0° or 180° bas

- Page 2042.MEASUREMENT CYCLE B-63874EN-1/02 Setting screen The displayed items are the same as for "Stylus Ball Center Offset Measurement-A" of "CALIBRATION (PROBE Z-AXIS DIRECTION)". Measurement motion Measurement motion is described below. <1> The reference workpiece is placed on the table, then this measu

- Page 205B-63874EN-1/02 2.MEASUREMENT CYCLE <7> Next, a rapid return movement is made by β, and 180-degree spindle orientation is executed, then a measurement is made at the feedrate specified by "MOVING MEAS. SPEED" in the range from that position to (β + γ). (Second measurement) <8> After a rapid return mo

- Page 2062.MEASUREMENT CYCLE B-63874EN-1/02 G code format When you press the INSERT key after entering necessary data, a G code program in the following format is stored in the machining program memory: G2103 Q D H V L R F P S Y ; Measurement result When G2103 is executed, center offsets of the stylus ball i

- Page 207B-63874EN-1/02 2.MEASUREMENT CYCLE 2.6.5 Stylus Ball Center Offset Measurement-B The offset between the center of the stylus ball and the center of the spindle is measured. NOTE A reference workpiece needs to be accurately placed on a table whose center position is known. When you select "STYLUS OFF

- Page 2082.MEASUREMENT CYCLE B-63874EN-1/02 Measurement motion Measurement motion is described below. <1> The reference workpiece is placed on the table, then this measurement cycle is executed. <2> When this measurement cycle is executed, a rapid movement is first made from the current position to the point

- Page 209B-63874EN-1/02 2.MEASUREMENT CYCLE f: Value of "FEED-RATE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." α: Value of "APPROACH DISTANCE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." β: Va

- Page 2102.MEASUREMENT CYCLE B-63874EN-1/02 2.7 TOOL MEASUREMENT (TOOL X-AXIS DIRECTION) 2.7.1 Milling Tool Measurement When the milling tool is oriented in the X-axis direction, the figure of the tool in the tool length direction and tool radius direction is measured. Measurement motion screen When you sele

- Page 211B-63874EN-1/02 2.MEASUREMENT CYCLE Measurement motion Measurement motion is described below. - Measurement of an offset value in the -X-axis direction (measurement of an offset value in the tool length direction) - When [AUTO] is selected in "SPECIFY OF X, Y, and Z SHIFT" The measurement motion desc

- Page 2122.MEASUREMENT CYCLE B-63874EN-1/02 - Measurement of an offset value in the -X-axis direction (measurement of an offset value in the tool length direction) - When a soft key other than [AUTO] is selected in "SPECIFY OF X, Y, and Z SHIFT" If the Z coordinate of the "sensor position for measurement in

- Page 213B-63874EN-1/02 2.MEASUREMENT CYCLE • If [OFSET-] is selected in "SPECIFY OF Z SHIFT", the approach point (Z coordinate) represents (Z coordinate of the "sensor position for measurement in the -X direction" of the touch sensor position - OFSD). • If [INPUT+] is selected in "SPECIFY OF Z SHIFT", the a

- Page 2142.MEASUREMENT CYCLE B-63874EN-1/02 - Measurement of an offset value in the -Z-axis direction (measurement of an offset value in the tool radius direction) The measurement motion described below is made when [AUTO] is selected in all input items of “SPECIFY OF X SHIFT”, “SPECIFY OF Y SHIFT”, and “SPE

- Page 215B-63874EN-1/02 2.MEASUREMENT CYCLE • If [INPUT+] is selected in "SPECIFY OF X SHIFT", the approach point (X coordinate) represents (X coordinate of the "sensor position for measurement in the -Z direction" of the touch sensor position + the value entered in "OFFSET/DIFFERENCE X"). • If [DIFF+] is se

- Page 2162.MEASUREMENT CYCLE B-63874EN-1/02 G code format When you press the INSERT key after entering necessary data, a G code program in the following format is stored in the machining program memory: G2110 P Q C F H D V R L Z W I S Y U J K E ; Measurement result When G2110 is executed, the result of measu

- Page 217B-63874EN-1/02 2.MEASUREMENT CYCLE 2.7.2 Turning Tool Measurement When the turning tool is oriented in the X-axis direction, the figure of the tool in the Z-axis direction and X-axis direction is measured. Measurement motion screen When you select "TURNING TOOL MEASUREMENT (TOOL X- AXIS)" on the too

- Page 2182.MEASUREMENT CYCLE B-63874EN-1/02 Measurement motion Measurement motion is described below. - Measurement of an offset value in the -X-axis direction Z X The measurement motion described below is made when [AUTO] is selected in all input items of “SPECIFY OF X SHIFT”, “SPECIFY OF Y SHIFT”, and “SPE

- Page 219B-63874EN-1/02 2.MEASUREMENT CYCLE If the coordinates of the "sensor position for measurement in the -X direction" of the touch sensor position are shifted from the coordinates of the tool measurement position, specify the shift in "SPECIFY OF X, Y, or Z SHIFT". For example, the motion described bel

- Page 2202.MEASUREMENT CYCLE B-63874EN-1/02 - Measurement of an offset value in the +Z-axis direction Z X The measurement motion described below is made when [AUTO] is selected in all input items of “SPECIFY OF X SHIFT”, “SPECIFY OF Y SHIFT”, and “SPECIFY OF Z SHIFT”. <1> A rapid movement is made from the cu

- Page 221B-63874EN-1/02 2.MEASUREMENT CYCLE If the coordinates of the "sensor position for measurement in the +Z direction" of the touch sensor position are shifted from the coordinates of the tool measurement position, specify the shift in "SPECIFY OF X, Y, or Z SHIFT". For example, the motion described bel

- Page 2222.MEASUREMENT CYCLE B-63874EN-1/02 - Measurement of an offset value in the -Z-axis direction Same as for measurement of an offset value in the +Z-axis direction The symbols used above have the following meanings: f: Value of "FEED-RATE FOR 1ST MEASUREMENT" in the measurement condition of the group n

- Page 223B-63874EN-1/02 2.MEASUREMENT CYCLE 2.8 WORK SET (PROBE X-AXIS DIRECTION) 2.8.1 End Face (X-axis Direction) Measurement The position of an end face in the X-axis direction is measured. When you select "X-AXIS DIRECTION WORK SETUP (PROBE X- AXIS)" on the centering menu selection screen of the measurem

- Page 2242.MEASUREMENT CYCLE B-63874EN-1/02 The symbols used above have the following meanings: f: Value of "FEED-RATE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." β: Value of "ESCAPING DISTANCE FOR 1ST MEASUREMENT" in the measurement condition of the

- Page 225B-63874EN-1/02 2.MEASUREMENT CYCLE 2.8.2 End Face (Y-axis Direction) Measurement The position of an end face in the Y-axis direction is measured. When you select "Y-AXIS DIRECTION WORK SETUP (PROBE X- AXIS)" on the centering menu selection screen of the measurement cycle, the following screen appear

- Page 2262.MEASUREMENT CYCLE B-63874EN-1/02 The symbols used above have the following meanings: f: Value of "FEED-RATE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." fb: Value of "FEED-RATE FOR APPROACHING START POINT" in the axis direction in the measu

- Page 227B-63874EN-1/02 2.MEASUREMENT CYCLE 2.8.3 End Face (Z-axis Direction) Measurement The position of an end face in the Z-axis direction is measured. When you select "Z-AXIS DIRECTION WORK SETUP (PROBE X- AXIS)" on the centering menu selection screen of the measurement cycle, the following screen appear

- Page 2282.MEASUREMENT CYCLE B-63874EN-1/02 2.8.4 Outside Diameter Measurement When the probe is oriented in the X-axis direction, the center position of the outside diameter of a circle is measured. When you select "OUTSIDE DIAMETER WORK SETUP (PROBE X-AXIS)" on the centering menu selection screen of the me

- Page 229B-63874EN-1/02 2.MEASUREMENT CYCLE Input screen for automatic workpiece offset value setting (turning side) This screen enables specification for setting a measured value as a workpiece origin offset value on the turning side. NOTE With the CNC for a machining center, the "WORK T" screen is not disp

- Page 2302.MEASUREMENT CYCLE B-63874EN-1/02 Measurement motion Measurement motion is described below. X <1> A rapid movement is made from the current position to the point specified by ("CENTER POINT Y" + ("OUTSIDE DIAMETER"/2 + α +r)) in the Y-axis direction and by "CENTER POINT Z" in the Z-axis direction.

- Page 231B-63874EN-1/02 2.MEASUREMENT CYCLE β: Value of "ESCAPING DISTANCE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." γ: Value of "OVERLAP DISTANCE FOR MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." ε:

- Page 2322.MEASUREMENT CYCLE B-63874EN-1/02 2.8.5 Inside Diameter Measurement When the probe is oriented in the X-axis direction, the center position of the inside diameter of a circle is measured. When you select "INSIDE DIAMETER WORK SETUP (PROBE X- AXIS)" on the centering menu selection screen of the meas

- Page 233B-63874EN-1/02 2.MEASUREMENT CYCLE Measurement motion Measurement motion is described below. X <1> A rapid movement is made from the current position to the point specified by ("CENTER POINT Y" + ("INSIDE DIAMETER"/2 - α - r)) in the Y-axis direction and by "CENTER POINT Z" in the Z-axis direction.

- Page 2342.MEASUREMENT CYCLE B-63874EN-1/02 β: Value of "ESCAPING DISTANCE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." γ: Value of "OVERLAP DISTANCE FOR MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." r:

- Page 235B-63874EN-1/02 2.MEASUREMENT CYCLE 2.8.6 Outside Width Measurement When the probe is oriented in the X-axis direction, the center position of a projection width is measured. When you select "OUTSIDE WIDTH WORK SETUP (PROBE X- AXIS)" on the centering menu selection screen of the measurement cycle, th

- Page 2362.MEASUREMENT CYCLE B-63874EN-1/02 Input screen for automatic workpiece offset value setting (turning side) This screen enables specification for setting a measured value as a workpiece origin offset value on the turning side. NOTE With the CNC for a machining center, the "WORK T" screen is not disp

- Page 237B-63874EN-1/02 2.MEASUREMENT CYCLE Measurement motion Measurement motion is described below. <1> For measurement in the Y-axis direction, a rapid movement is made from the current position to the point specified by ("CENTER POINT Y" + ("PROJECTION WIDTH"/2 + α + r)) in the Y-axis direction and by "C

- Page 2382.MEASUREMENT CYCLE B-63874EN-1/02 α: Value of "APPROACH DISTANCE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." β: Value of "ESCAPING DISTANCE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND

- Page 239B-63874EN-1/02 2.MEASUREMENT CYCLE 2.8.7 Inside Width Measurement When the probe is oriented in the X-axis direction, the center position of a groove width is measured. When you select "INSIDE WIDTH WORK SETUP (PROBE X- AXIS)" on the centering menu selection screen of the measurement cycle, the foll

- Page 2402.MEASUREMENT CYCLE B-63874EN-1/02 Measurement motion Measurement motion is described below. X <1> For measurement in the Y-axis direction, a rapid movement is made from the current position to the point specified by ("CENTER POINT Y" + ("GROOVE WIDTH"/2 - α - r)) in the Y-axis direction and by "CEN

- Page 241B-63874EN-1/02 2.MEASUREMENT CYCLE α: Value of "APPROACH DISTANCE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND." β: Value of "ESCAPING DISTANCE FOR 1ST MEASUREMENT" in the measurement condition of the group number specified in "MEASUREMENT COND

- Page 2422.MEASUREMENT CYCLE B-63874EN-1/02 2.8.8 C-axis Outside Width Measurement When the probe is oriented in the X-axis direction, the center angle of a projection width in the C-axis direction is measured. When you select "C-AXIS OUTSIDE WIDTH WORK SETUP (PROBE X-AXIS)" on the centering menu selection s

- Page 243B-63874EN-1/02 2.MEASUREMENT CYCLE Measurement motion Measurement motion is described below. <1> A rapid movement is made from the current position to the point specified by "MEASURE POINT Y" and "MEASURE POINT Z". <2> Next, a rapid movement is made in the C-axis direction to the point ("CENTER ANGL

- Page 2442.MEASUREMENT CYCLE B-63874EN-1/02 The symbols used above have the following meanings: fa: Value of "FEED-RATE FOR APPROACHING START POINT" in the measurement condition of the group number specified in "MEASUREMENT COND." Rapid traverse rate when bit 2 (RPDF) of parameter No. 12380 is set to 1. fb:

- Page 245B-63874EN-1/02 2.MEASUREMENT CYCLE 2.8.9 C-axis Inside Width Measurement When the probe is oriented in the X-axis direction, the center angle of a groove in the C-axis direction is measured. When you select "C-AXIS INSIDE WIDTH WORK SETUP (PROBE X-AXIS)" on the centering menu selection screen of the

- Page 2462.MEASUREMENT CYCLE B-63874EN-1/02 Measurement motion Measurement motion is described below. <1> A rapid movement is made from the current position to the point specified by "MEASURE POINT Z" and "MEASURE POINT Y". <2> Next, a rapid movement is made in the C-axis direction to the point specified by

- Page 247B-63874EN-1/02 2.MEASUREMENT CYCLE The symbols used above have the following meanings: fa: Value of "FEED-RATE FOR APPROACHING START POINT" in the measurement condition of the group number specified in "MEASUREMENT COND." Rapid traverse rate when bit 2 (RPDF) of parameter No. 12380 is set to 1. fb:

- Page 2482.MEASUREMENT CYCLE B-63874EN-1/02 2.9 MEASURE (PROBE X-AXIS DIRECTION) 2.9.1 End Face (X-axis Direction) Measurement The position of an end face in the X-axis direction is measured. When you select "X-AXIS DIRECTION MEASUREMENT (PROBE X-AXIS) on the post-machining inspection menu selection screen o