FANUC Series 30i-A/31i-A5 Tool Posture Control of Toll Center Point Control for 5-axis Machining Additional Manual Page 8

Additional Manual

Ed.

Apprv.

Person

Page

Name No.

Date

Person

Contents

Date

FANUC Series 30i-A/31i-A5

Tool Posture Control of Toll Center Point Control

for 5-axis Machining

A

-79294E

2004.2.25

8

/

12

FANUC LTD.

2004.4.12

02

The part of (2) is changed.

2004.9.22

03

The function name is updated.

2004.11.16

04

The part of (4) is changed.

2004.12.17

05

The part of (5) is changed.

In the case that the tool posture is commanded with I,J,K (G43.5 : Tool center

point control type II), Tool posture control has the following function.

- It checks if the tool posture can be near Singular posture in each block.

- When the tool posture can be near Singular posture in the block, it changes

the tool posture (the rotary axis postion) at the end of the block so that the

tool posture passes the singular posture.

When the difference between a tool posture during a block and the singular

posture is less than the parameter No.19738, the tool posture is regarded as ‘near

singular posture’. If the parameter No.19738 is 0, the tool posture at the end of a

block is not changed.

And, as the result of the change of the tool posture at the end of a block, if the

Work-piece side rotary axis position is changed larger than the parameter

No.19739, the change is not done.

Moreover the change is not done when the tool posture at the start or end of the

block is the singular posture, or when the tool posture becomes the singular

posture during execution of the block.

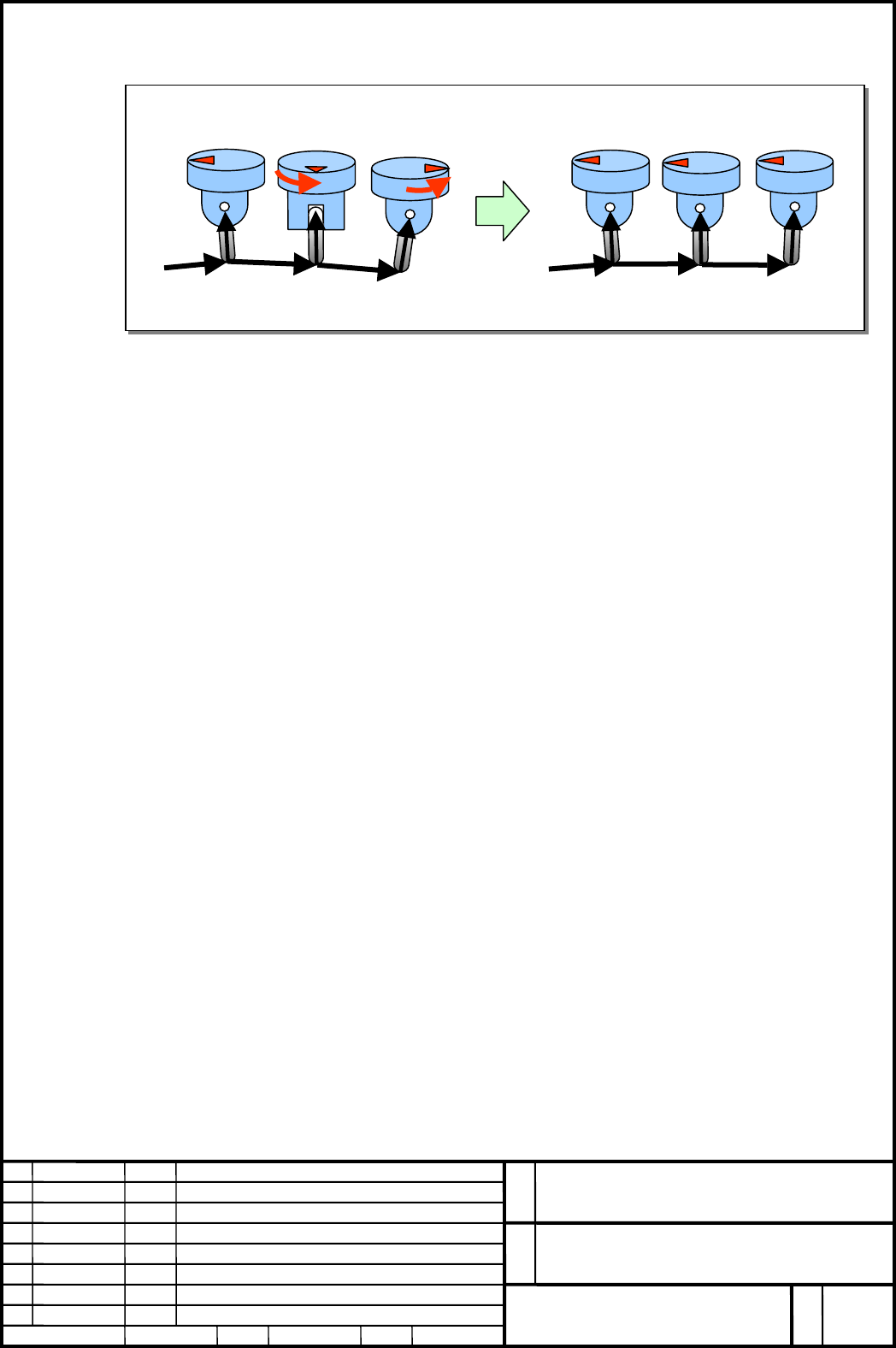

Fig.5 : Change of Tool posture at the end of block

C-axis rotates very rapidly and

largely near Singular posture.

So, the rapid and large C-axis rotation

should be avoided by travelling just

through Singular posture.

To travel the Singular posture, the end

point is modified within the tolerance.

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

Contents Summary of FANUC Series 30i-A/31i-A5 Tool Posture Control of Toll Center Point Control for 5-axis Machining Additional Manual

- Page 1FANUC Series 30i-A/31i-A5 Tool Posture Control of Tool Center Point Control for 5-axis Machining Specifications FANUC Series 30i-A/31i-A5 Name Tool Posture Control of Toll Center Point Control for 5-axis Machining 05 2004.12.17 The part of (5) is changed. 04 2004.11.16 The part of (4) is changed. No

- Page 2General With Tool Center Point control, the tool center point moves on the commanded path. Here, usually the tool posture(tool direction) is not controlled, because the two rotary axes move independently. (Conventional control) This new fearture 'Tool Posture Control of Tool Center Point control for

- Page 3Format Tool Posture Control G43.4 IP α β H P ; Tool Center Point control (TYPE1) G43.5 IP H Q P ; Tool Center Point control (TYPE2) IP : In the absolute mode, the end position of Tool Center Point In the incremental mode, the movement value of Tool Center Point α, β : In the absolute mode, the end p

- Page 4Example : O0010 With Tool posture control, at the blocks … N20 - N80 of the left program O0010, the N10 G90 G00 X30.0 Y-30.0 Z0.0; N20 G43.5 H1 P1; side of the work-piece can be machined. N30 G42.6 D2; The command G42.6 in N30 is for Tool (4) N40 G01 X20.0 Y-20.0 I-1 J1 K2 F_; Radius Compensation fo

- Page 5V : Actual vector of the tool posture Control point Vs Tool Center Ve Point End point of a block Start point of a block Commanded program Actual Tool Center Point th Plane made by Vs and Ve. The actual vector V lies on this plane. Ve : End vector of Tool Vs : Start vector of Tool length compensation

- Page 6‘Tool side rotary axis’ and ‘Work-piece side rotary axis’ In this paragraph, ‘Tool side rotary axis’ and ‘Work-piece side rotary axis’ which are used in the next paragraph are explained. It is required to take notice of ‘Singularity’ in the case of Tool Center Point Control Type II. On a 5-axis mach

- Page 7Example : On a tool rotation type machine which has C axis(master axis around Z axis) and B axis(slave axis around Y axis) and the reference tool direction in Z axis direction, the singular position is B=0,+/-180,,,,deg. Then, the tool posture is the singular posture at C=any-deg. When B=0 (singular

- Page 8(2) (2) (2) (2) (2) (2) (2) (2) (2) (2) (2) (2) (2) (2) C-axis rotates very rapidly and So, the rapid and large C-axis rotation (2) largely near Singular posture. should be avoided by travelling just (2) through Singular posture. (2) To travel the Singular posture, the end (2) point is modified with

- Page 9When this angle is less than Parameter No.19738, Tool posture is regarded as ‘near Singular posture’. Singular posture Tool posture Fig.6 : Tool posture near Singular posture When the tool posture can be near Singular posture in a block, the rotary axes positions at the block end, which are calculat

- Page 10Note In the case that the vectors of Tool length compensation at start/end of a block are the same. In the case that the vectors of Tool length compensation at start and end of a block are the same(same direction or reverse direction), Tool Posture Control does not work and Conventional control work

- Page 11Parameter #7 #6 #5 #4 #3 #2 #1 #0 19604 TPC [Input type] Setting input [Data type] Bit path #0 TPC In the case that there is no address P at the start of Tool center point control for 5-axis machining (G43.4/G43.5), 0 : Tool posture control does not work. 1 : Tool posture control works. #7 #6 #5 #4

- Page 1219739 Angle to decide that the tool posture at block end is not changed [Input type] Parameter input [Data type] Real path [Unit of data] degree [Valid data range] 9 digit of minimum unit of data (refer to standard parameter setting table(A)) (When the increment system is IS-B, -999999.999~+999999.9